Understanding Customer Needs — The First Step to Success

At NUOXIN, every project begins with understanding.

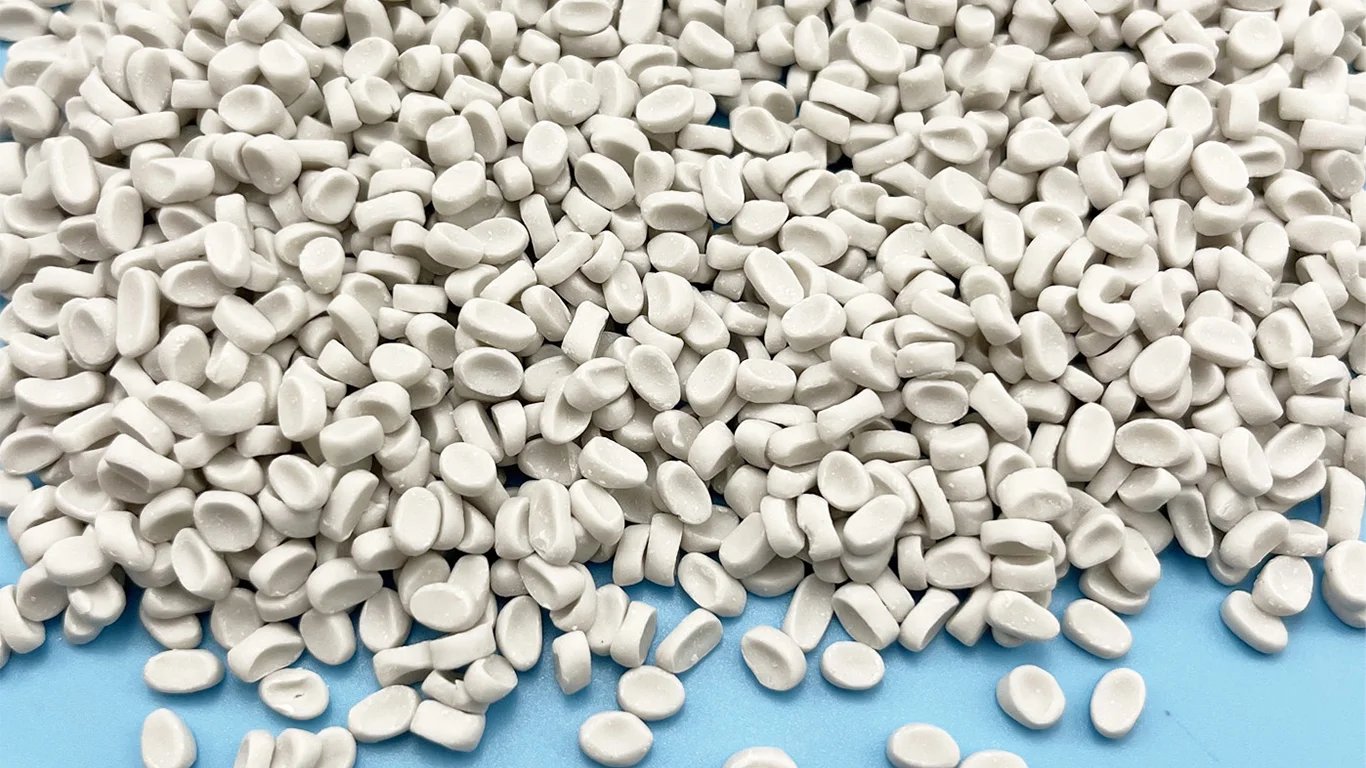

We carefully analyze customer applications — such as film blowing, injection molding, extrusion, or 3D printing — to choose the most suitable masterbatch formulation.

Our experienced sales and technical teams ensure 24-hour response time to every inquiry, providing fast and professional support.

NUOXIN believes that accurate communication is the key to every successful cooperation. By understanding your end use, carrier resin, and color requirements, we tailor the best-performing masterbatch for your production.

Sample Development & Custom Color Matching

NUOXIN provides Pantone / RAL-based color matching, ensuring color consistency across different batches.

Our laboratory performs multiple dispersion and heat stability tests before confirming the final formula.

Customers can receive free samples (50g–25000g) for testing, and fine-tuning is done until satisfaction is achieved.

Color Masterbatch Matching Process

| Step | Process | Description |

| 1 | Color Sample | Customer provides Sample or Pantone / RAL reference |

| 2 | Lab Test | Pigment blending and dispersion testing |

| 3 | Sample Delivery | Free 50–500g sample provided |

| 4 | Customer Feedback | Adjustments made until approved |

| 5 | Mass Production | Final formula confirmed and locked |

High-Quality Production with Strict Quality Assurance

NUOXIN implements a five-level quality inspection system, certified by ISO, ROHS, FDA, MSDS, and TDS.

Each batch of raw materials and finished products undergoes triple inspection, ensuring a product qualification rate above 99.99%.

We use imported pigments and polymer carriers for stable dispersion and consistent performance in every batch.

Quality Control System Overview

| Inspection Level | Test Item | Equipment Used | Standard |

| Raw Material | Moisture & Purity | Moisture Analyzer | ISO 9001 |

| Mixing Stage | Pigment Dispersion | Spectrophotometer | ROHS |

| Extrusion Stage | Melt Flow Index | MFI Tester | FDA |

| Final Product | Color Stability | UV Chamber | MSDS |

| Random Sampling | Visual & Functional Test | Microscopic Camera | TDS |

Fast Delivery & Reliable Logistics

With 100,000 tons of annual production capacity and 500 tons of ready stock, NUOXIN guarantees 24-hour fast delivery for standard grades.

We cooperate with international freight forwarders to provide FOB, CIF, and DDP shipping terms, ensuring smooth customs clearance and on-time delivery worldwide.

Whether you need small trial orders or full container shipments, NUOXIN’s flexible production and logistics system can meet your requirements quickly and efficiently.

Technical Support & After-Sales Service

NUOXIN offers continuous technical guidance throughout the customer’s production process.

If any issue arises — such as color deviation, moisture, or poor dispersion — we provide remote support or replacement within 7 days.

Our service does not stop at shipment — it continues with every meter of film or plastic part produced by our customers.

We also provide material compatibility advice, processing temperature optimization, and troubleshooting guides for better production efficiency.

Conclusion: Reliable, Efficient, and Customized Masterbatch Solutions

From your first inquiry to final delivery, NUOXIN provides a seamless, one-stop masterbatch solution that saves time, reduces cost, and ensures consistent quality.

We take pride in being a trusted global partner for color masterbatch, black masterbatch, white masterbatch, filler masterbatch, and desiccant masterbatch production.

✨ Contact us today for free samples and expert formulation support —

Let NUOXIN empower your plastics manufacturing with stable color, performance, and efficiency.