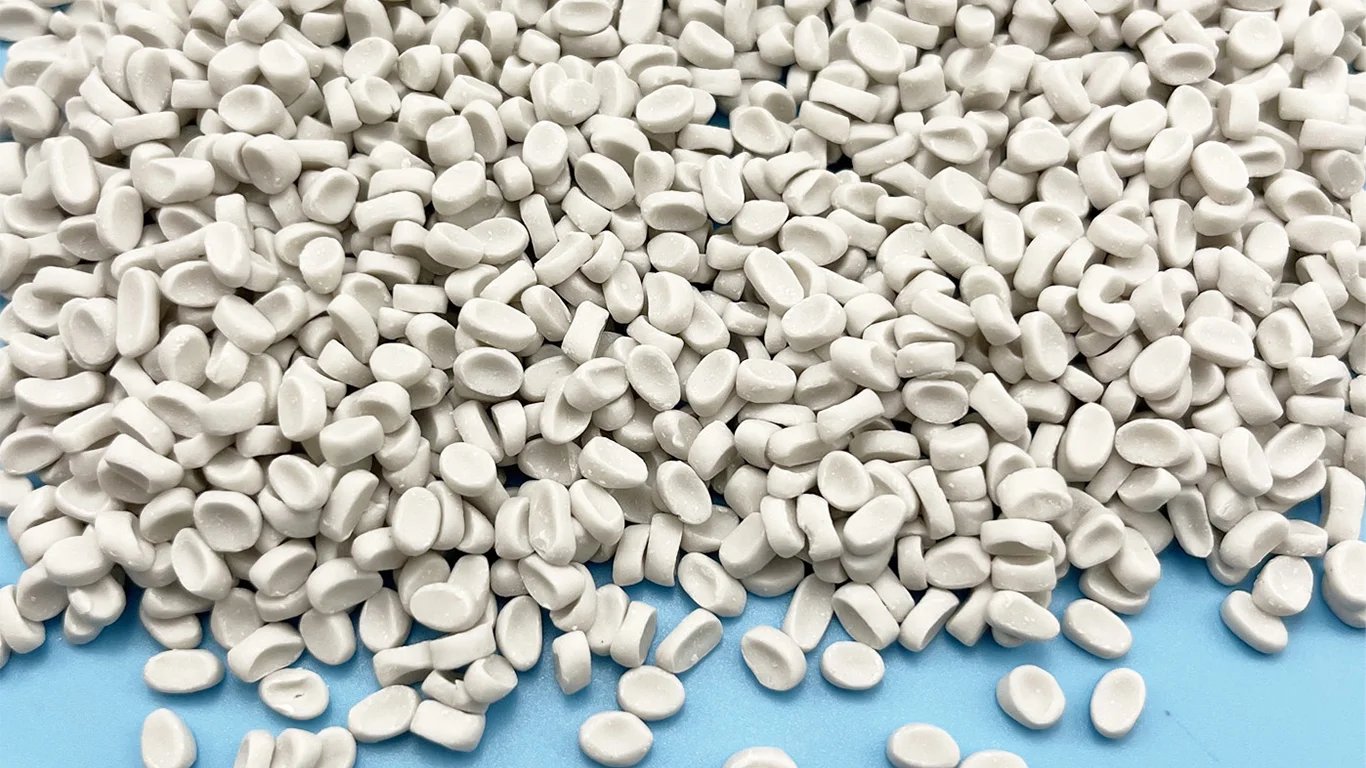

November 2025 — NUOXIN today announces the launch of its new PP Filler Masterbatch Series: PP-2, PP-3, PP-4, PP-5. Formulated with high-grade calcium carbonate as the primary filler and produced via advanced twin-screw extrusion, this series delivers stable processing, improved rigidity, and cost-saving benefits for a wide range of injection-molding applications.

Dual-Purpose Design: Use as a Filler or as a Direct PP Substitute

NUOXIN’s PP series is engineered for two practical uses:

✔ As a Filler Masterbatch

When blended with virgin PP resin, the masterbatch provides:

Lowered material cost per part

Increased stiffness and dimensional stability

Improved thermal behavior in some processing windows

Better flow for certain geometries, assisting production efficiency

✔ Can Be Used Directly for Injection Molding

Selected models in the PP-2 / PP-3 / PP-4 / PP-5 range are optimized so they can be used directly as a partial or full replacement for virgin PP in appropriate applications — enabling significant formulation simplification and cost reduction while maintaining acceptable end-use performance for many product types.

Suitable applications include:

Daily-use consumer goods

Structural and engineering components where stiffness is required

Appliance housings and panels

Plastic containers, trays and pallets

Handles, brackets and general injection parts

Why Calcium Carbonate? — Advantages as a Filler

Calcium carbonate (CaCO₃) is a widely used inorganic filler in polymer modification. NUOXIN selects high-quality, controlled-particle calcium carbonate to achieve predictable performance:

Improves stiffness and dimensional control due to its particulate reinforcement effect

High bulk density enables cost savings (more filler per volume)

Brightness and surface finish benefits for certain formulations (can improve opacity and surface appearance)

Thermally stable in common PP processing conditions

Widely available and cost-effective, helping lower overall material cost

NUOXIN controls particle size distribution and dispersion during compounding to minimize negative impacts on impact strength and to keep processing behaviour consistent for moulding lines.

Product Model Overview

| Model | Key Features | Recommended Applications |

| PP-2 | Medium calcium carbonate loading, general-purpose | Thin-wall consumer items, household goods |

| PP-3 | Medium-high loading, improved stiffness | Appliance housings, trays |

| PP-4 | High loading, enhanced dimensional stability | Structural parts, engineering components |

| PP-5 | Cost-optimized grade; suitable for direct molding | High-volume injection parts, cost-driven production |

Supporting Cost-Effective & Sustainable Manufacturing

As manufacturers pursue lower costs and more sustainable production, well-engineered filler masterbatches play a key role. NUOXIN’s PP-2/3/4/5 series aims to reduce material costs while maintaining production stability. In addition, using mineral fillers such as calcium carbonate can reduce reliance on virgin polymers and, in many formulations, lower product carbon footprint per unit.

A NUOXIN spokesperson said:

“By offering calcium carbonate-based masterbatches that are easy to process and economically attractive, we help customers improve their product competitiveness without sacrificing manufacturability.”

About NUOXIN

NUOXIN is a China-based masterbatch manufacturer with more than 10 years of experience. Product lines include:

Color Masterbatch

Black & White Masterbatch

Calcium Carbonate Filler Masterbatch & Talc/Other Filler Masterbatches

Desiccant Masterbatch (Calcium Oxide Based)

The company operates advanced twin-screw lines and a multi-stage quality inspection system, serving customers across 30+ countries.